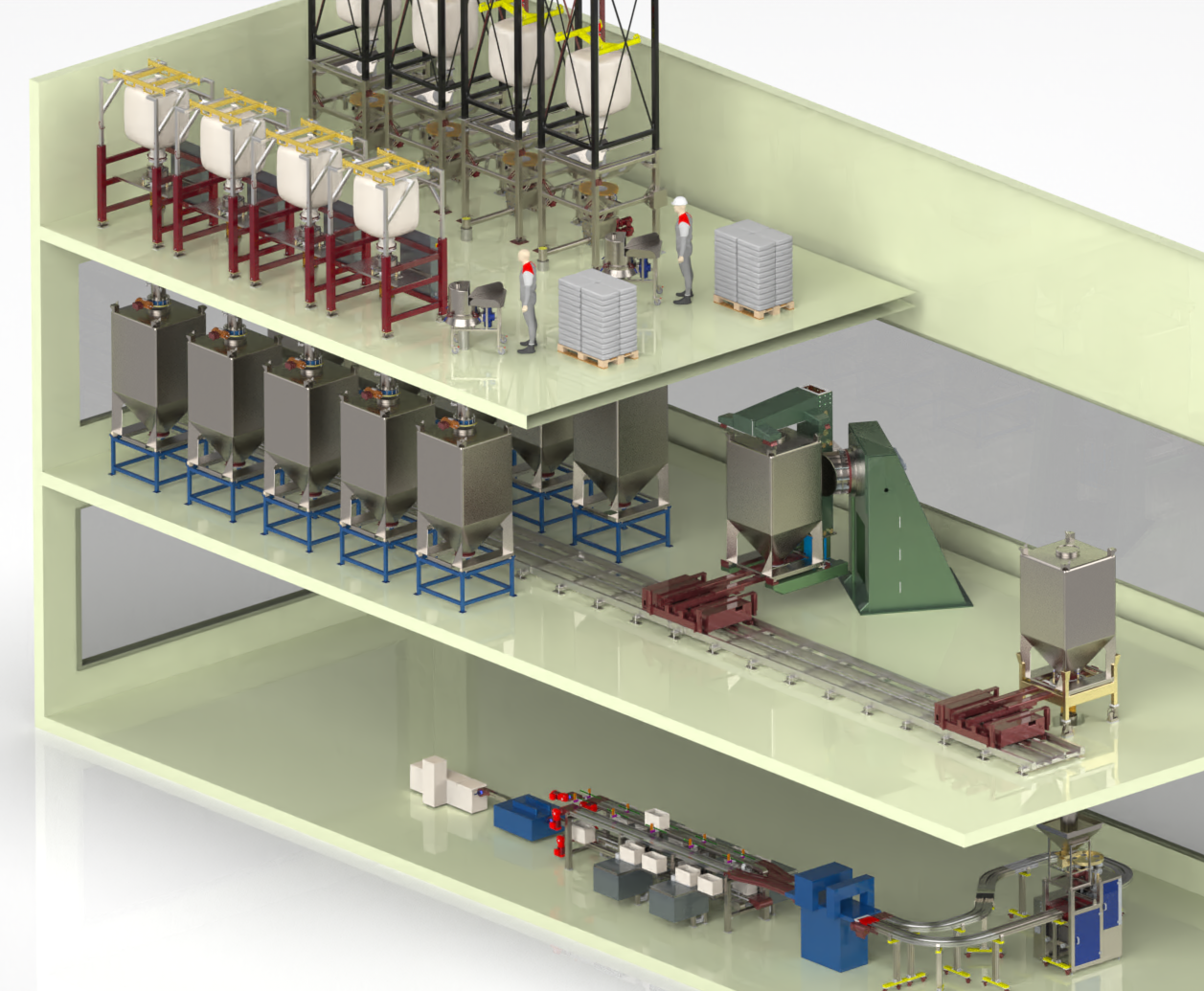

Planning of complex, automated production

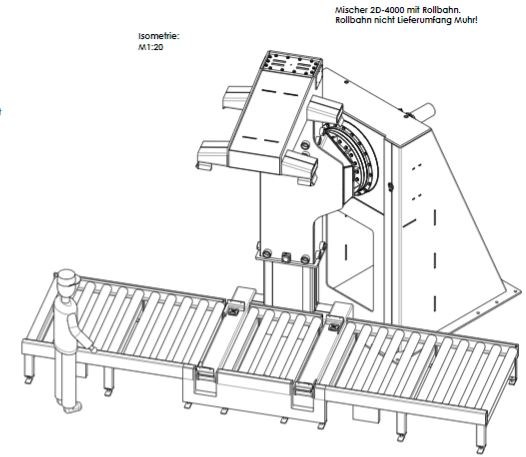

Our IBC container systems are suitable for dust-free filling and emptying of process engineering systems such as mixers, screens, furnaces, etc. To optimize your workflow, transport and docking processes can also be automated. Whether free-flowing or difficult-flowing media, we have the favourable and suitable solution ready. Cleaning-friendly and dust-proof transitions, suitable for fast product changes and flexible powder handling for feeding through internal transport systems such as standard industrial trucks, cranes, roller conveyer, lifter, etc. are part of our scope of delivery.

pic.: IBC Cone valve systems for batch dosing

The IBC containers as well as big bags (FIBC) are automatically placed on the container feed station with the help of roller conveyors or shuttle systems (AGVs) and emptied. Automatic identification systems (barcode, RFID, etc.) prevent confusion. Depending on the containment requirement, docking is carried out by different types of docking adapters, which ensure dust-free product feeding into the subsequent system. The container remains on the container feed station as long as the bulk material type is involved in the recipe. In the event of a change, only the emptying fitting is closed and the container fixation is unlocked. The IBC can then be transferred back to the warehouse at defined transfer points. Optionally, the control is also available interfaces to higher-level ERP systems.

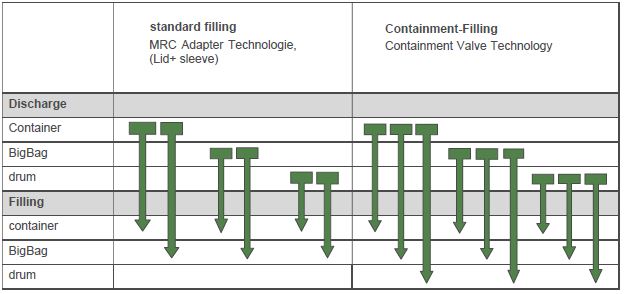

The bulk material is first transferred to containers via appropriate filling stations. Following filling/discharge adapter are available:

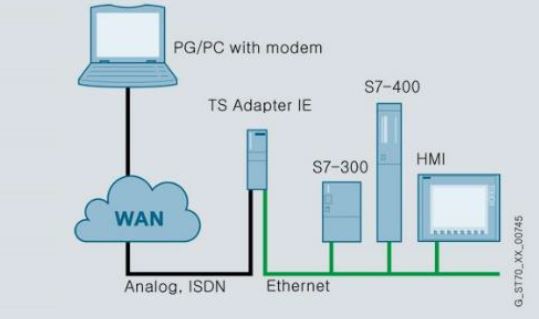

Control systems

Siemens S7 hardware is used as standard for the control system. By using scales at the feeding points, batch dosing can be carried out during filling and emptying. Recipe management can be organized locally or in the customer’s ERP

Local receipt management of ingredients and hardware interfaces such as Profibus, Ethernet etc. to communicate with ERP systems available.

Tests with the respective media can be carried out in our test center with test facilities for tumble blending, mixing, emptying and dosing. Contact us and we will arrange appropriate tests with you at short notice.