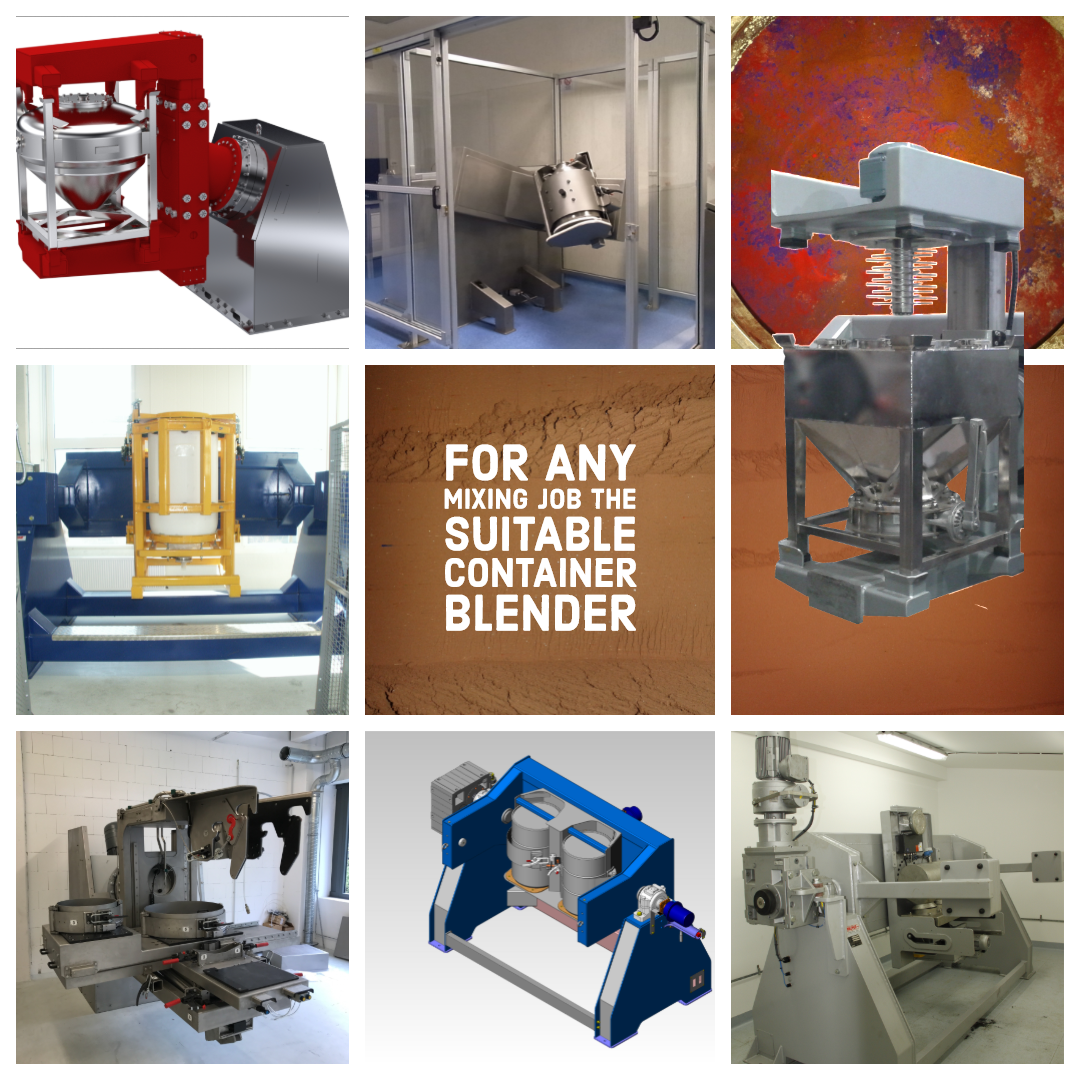

Different IBC blender mixing systems for a homogenous mix

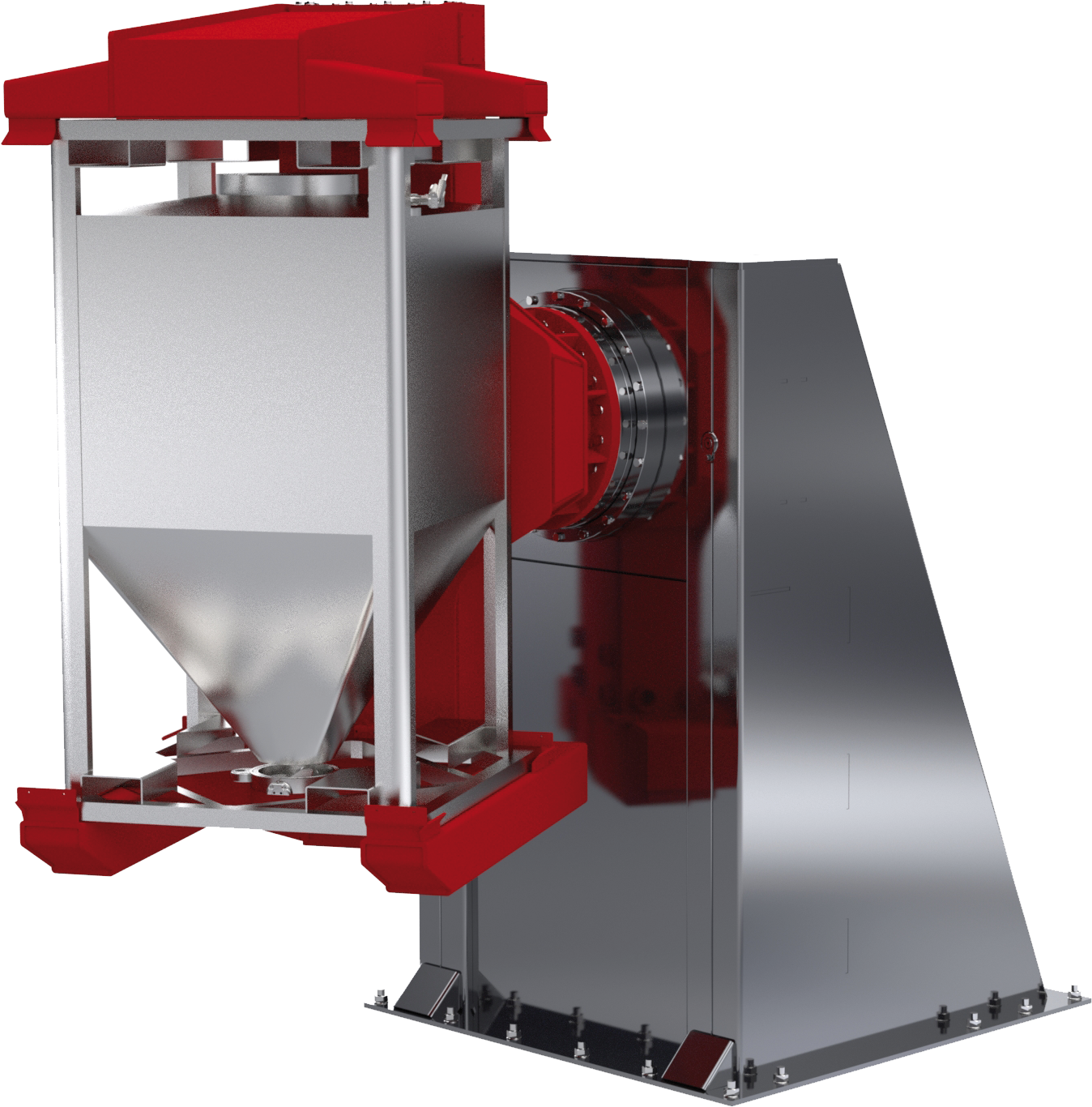

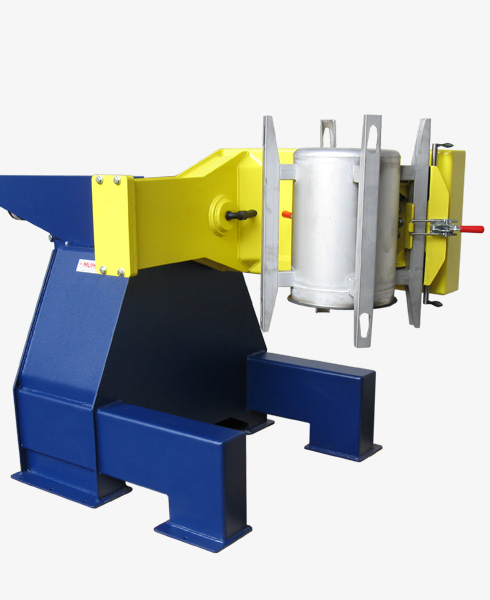

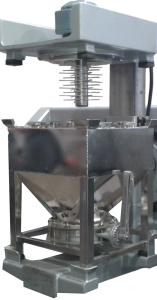

2D Container mixing principle:

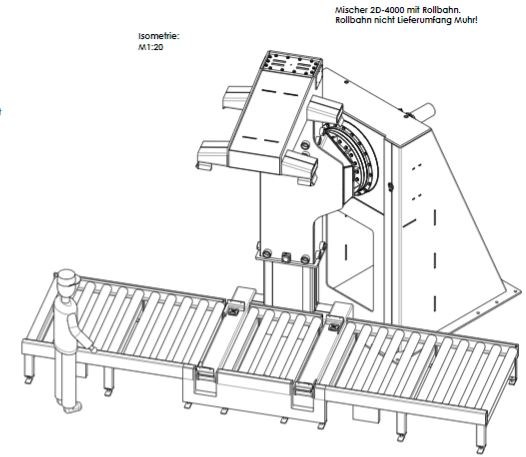

An IBC blender creates the mixing effect by a two-dimensional motion field of powder particles while rotating the blending container around its horizontal axis. Mixing container/drums are available in sizes from 5 to 4,000 litres with a max. batch weight of 5 to. The loading of the mixing container by pallet-/or forklift truck is standard. Upon request we offer also an automatized loading process by crane-, roller conveyer- or shuttle systems.

Advantages tumble blending against ribbon blender:

- adapted design of the mixing container /drum depending on filling medium

- cost-effective: no cleaning neccessary means no loss of mixing capacity

- no cross contamination: individual container/drum for raw materials

- we offer special armatures to avoid segregation when filling or dicharge the batch container

- Gentle mix for sensitive powders

pic.: container blender 2D mixing principle / mixing result after one turn

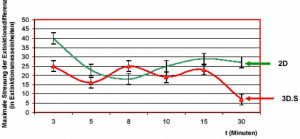

The 3D.S mixer is a free-fall mixer with two rotation axis and separate motor power. Thanks to these 3D space motion dynamics the blending time is shorter and you get a more homogenous mix. A continiously changing 3-dimensional crossing and rolling movement of the powder avoid dead zones and regular flow fields in the mixing container. This effect guarantees a perfect mixing result.

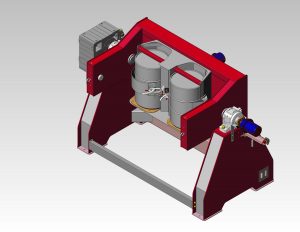

pic.: container blender: 3DS mixing principle /mixing result after one turn

3D drum Mixer / drum blender examples:

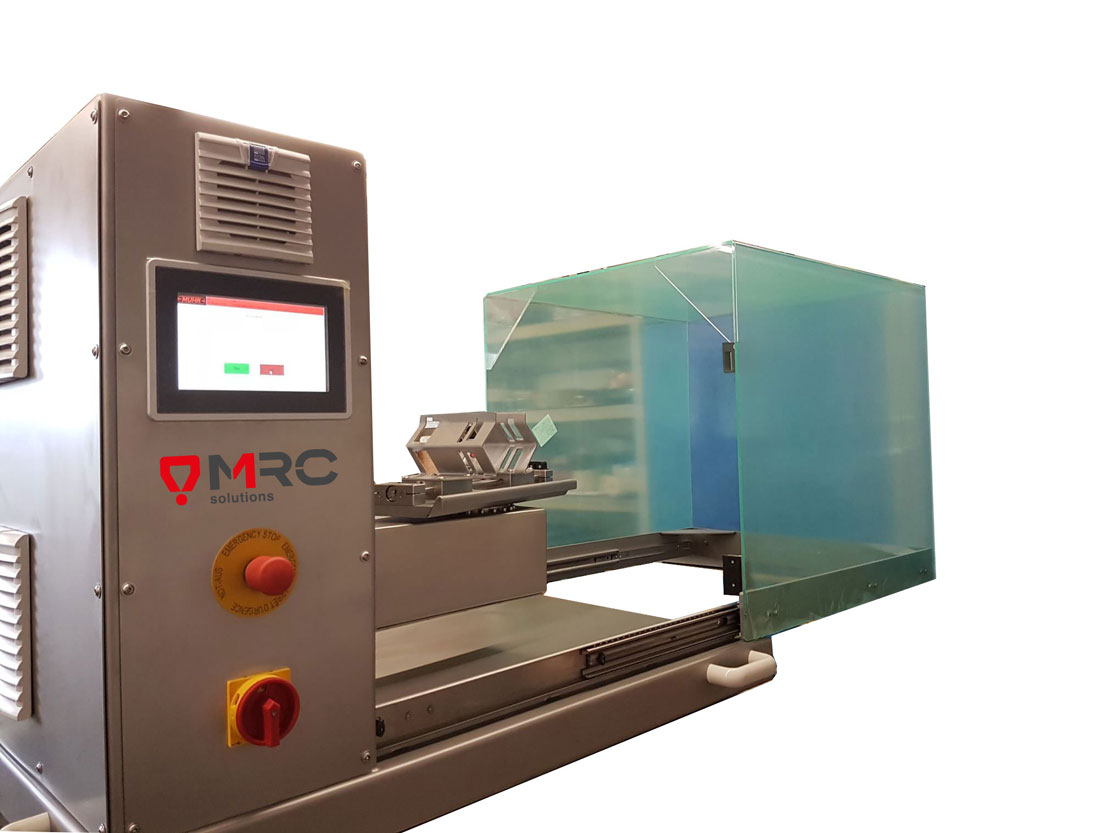

control system IBC blender:

Mixing parameters:

- stepless speed rotation 5-17 rev/min

- rotation clockwise/unclockwise

- data base for different mixing recipes

- upon request: variable mixing container for different batch sizes

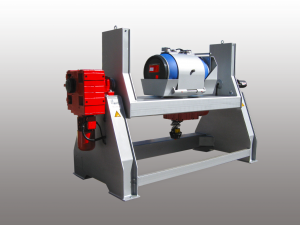

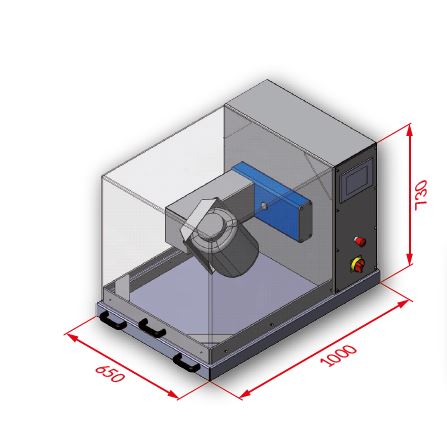

Laboratory Blender

Features:

– 2D/3D Mixing principle

– batch sizes up to 30 kg

– multiple clamp system for batch bin

– OP terminal with recipe management

MRC laboratory blender are suitable for mixng smaller batches under production conditions. Mixing Results gained from these blending are a reliable scale for real manufacturing process. Set up of parameters such as RPM and mixing time are stepless adjustable.

Option: Turbo Mixer unit for crushing lumps