Customized container in different materials for industrial applications

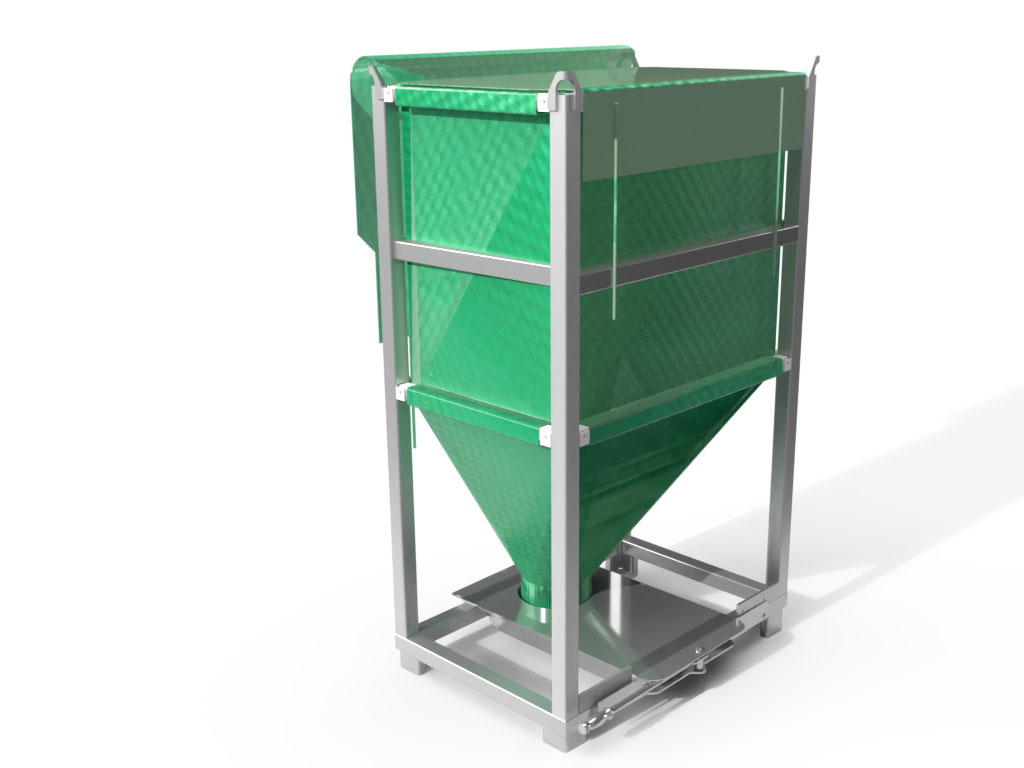

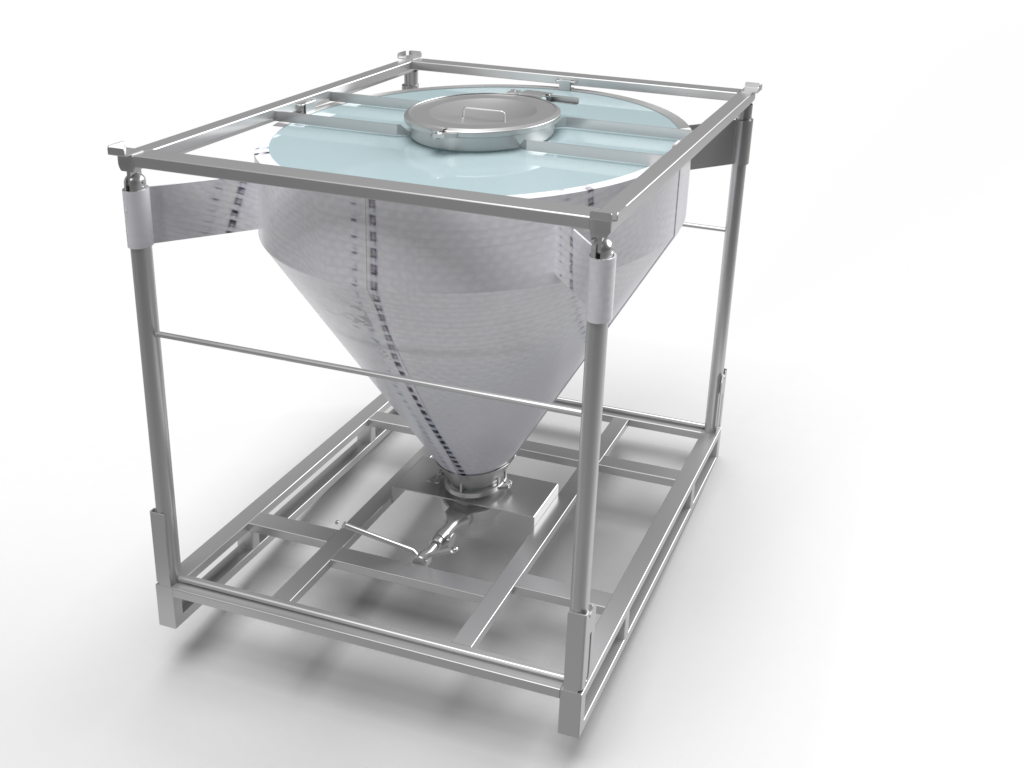

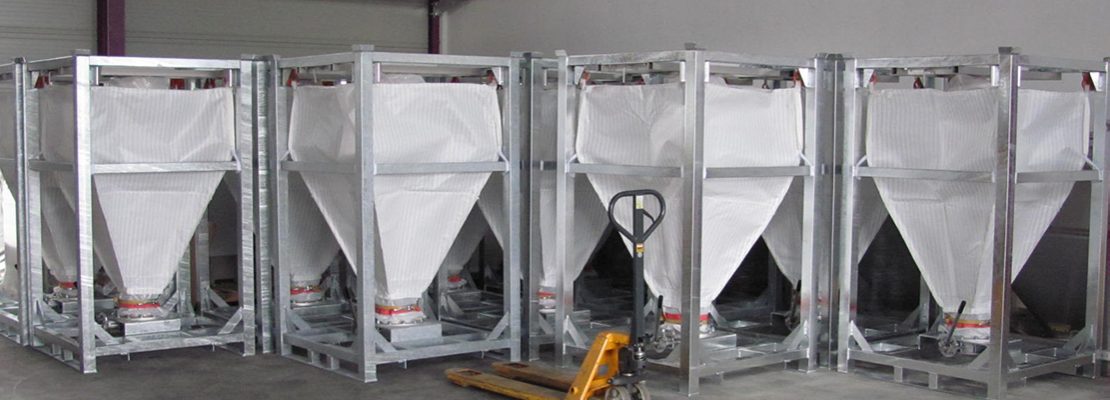

If you need tailor-made solutions, whether round, cubic, cylindrical or any other shape, we have the ideal solution for you. Our great manufacturing expertise make us the ideal partner for your particular application. We develop, design and produce your tank, container, IBC or other customized container.

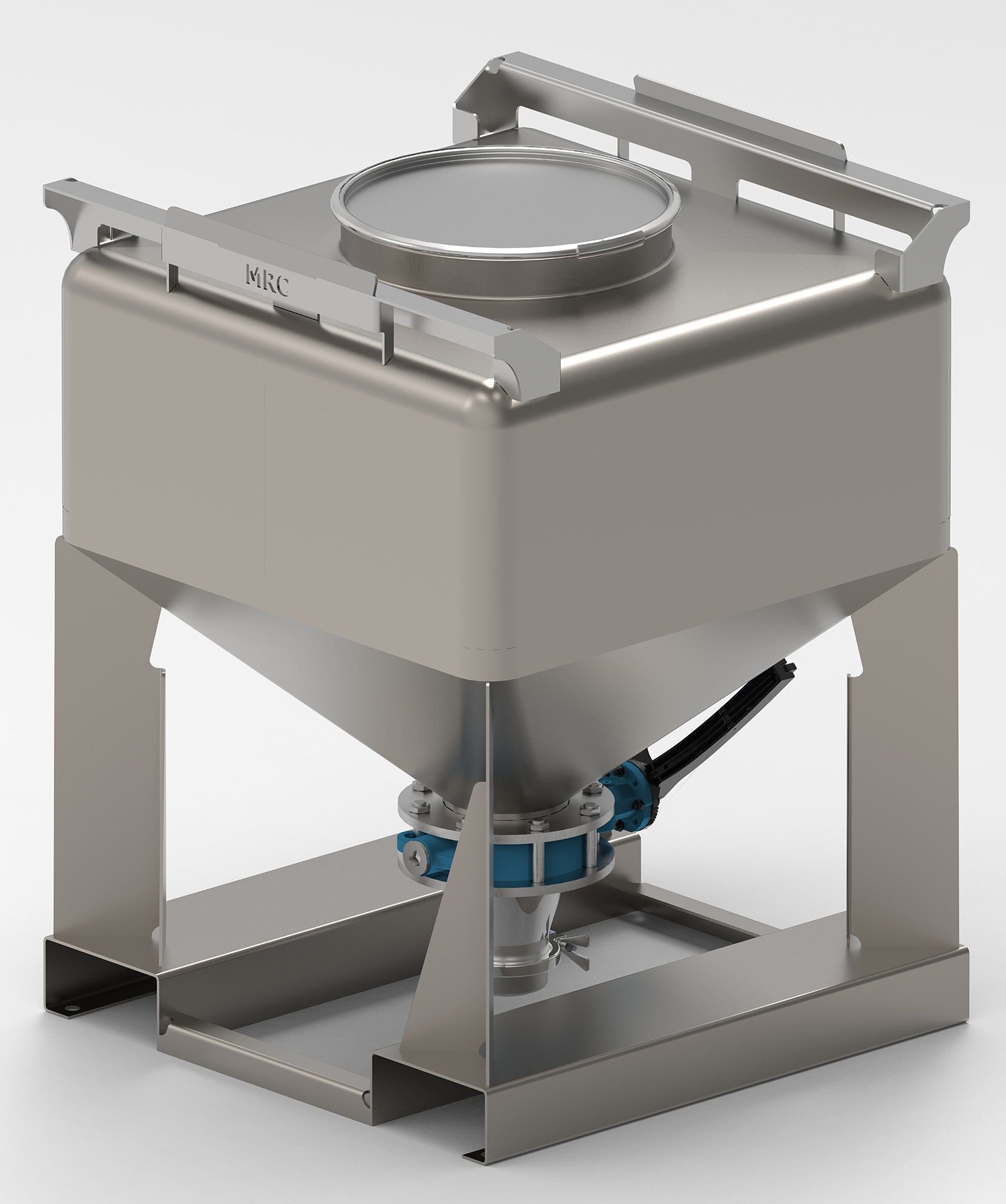

Our easy-to-clean manhole lid designs, containment valves for dust-free filling and discharge or PE Inliner systems are very important components of these concepts, all parts available as retrofits for existing packaging such as metal IBC etc.

Design details of our container system:

- nominal volumes 50 Liter up to 3.000 Liter

- dimensions 600 x 600 mm up to 1200 x 1200 mm footprint, customized design upon request

- outlet valve with patented docking unit for dust free powder handling

- Easy-to-clean outlet armatures for contained filling/discharge: cone valve DN100/200

and butterfly valves DN250 and suitable discharge stations - upon request: DN 250 Dosing Iris Valve, stepless setting of flow diameter, open top

- Safe handling: robust, lockable clamping rings

- gentle discharge: sensible media such as tablets, chips, etc.

- retrofit design components: updating of equipment from other manufacturers

We analyse your production process and develop a suitable solution for container handling with stainless steel IBC or Flex Bag Systems for a dust-free transfer of bulk materials. Our object is an effective upgrade of your poduction to improve the containment level for a safe powder handling. This includes the use of tank materials such as stainless steel, PP Flex Bag (FIBC) or HD/LD-PE plastic.