Customized bags and PE inliner with fitting/valves

For safe and economic stock of liquids or powders we offer special designed PE Inliner or PE bags to suit onsite packaging such as container, drums, vessels, bottles etc. Individual valves and nozzles for filling and discharge are also available.

- PE Inliner also in smaller quantities available

- tailormade dimensions for volumes of 0,5 L to 1.000 Liter

- filling/discharge: various valves and fittings up to DN 100 available

- foil material LD-PE up to 200 μm thickness

suitable for tanks: container, drums, mixing vessels etc.

Suitable for liquid and pasty products or bulk goods in tanks such as container (IBC), mixing vessels, drums etc. With the contamination by sticky or pasty medium expensive efforts for cleaning rise up considerably. To avoid the cleaning of the tank we design special inliners for container, drums vessels etc. They are liquid-proof and thus suitable for many applications, including valves and nozzles for filling/discharge such as nozzles, butterfly valves, ball valves etc.

Option: all valves and nozzles of the inliner in tamper proof design for confirmation of freshness of your medium

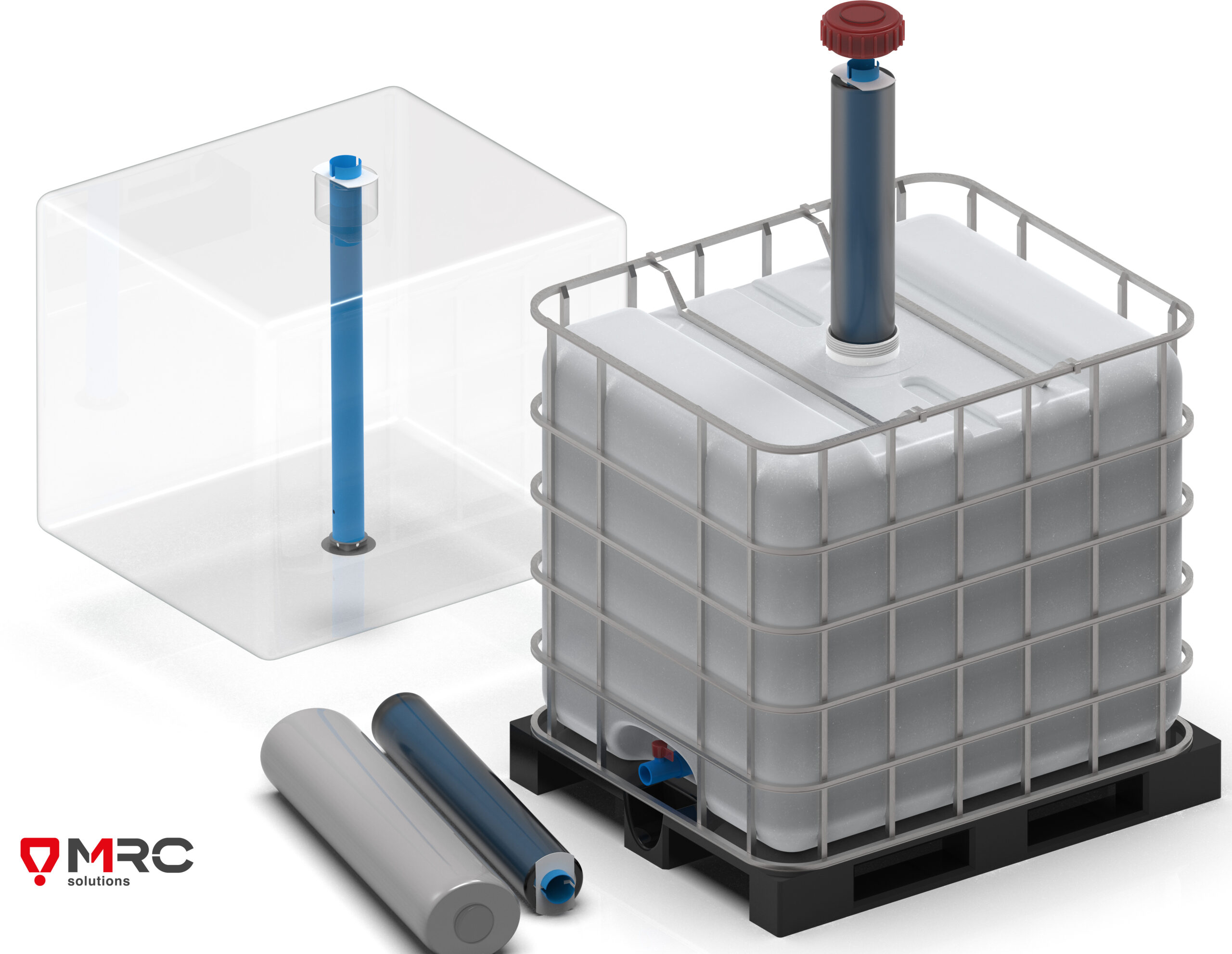

Inliner for plastic IBC

- assembly of the inliner into IBC within one minute

- suitable for all common plastic IBC Container Type Schuetz, Mauser etc.

- complete emptying (depending on medium up to 99%)

- safe handling: Bag formation or pockets and strain load due to incorrect installation of the inliner are excluded

- favourable PE Inliner price: Cost for cleaning the IBC are significantly higher

- optional: antistatic or food-safe FDA EG1935/2004 certified foils available

FIBC 1000: Conversion Kit for a standard IBC frame

FLEX KIT, quick assembly of an IBC to an FIBC:

components:

1- IBC frame 2-PP mesh bag 3-LD-PE Inliner 4-outlet valve

Easy assembly:

- fixing of PP mesh bag (2) within IBC frame (1)

- set in PE Inliner (3) with outlet valve

- fixing outlet valve (4) at protection plate

advantages:

- economical packaging

- hygienic

- no cost for cleaning

- better discharge than IBC

- flexible, suitable to all types of IBC such as Schütz, Mauser Sotralenz etc.

- C-Clip fixing tool for 2″/3″ Outlet Valve

- nominal volume: 1000 l

LD PE Inliner for drums, hobbocks, buckets, pots etc.

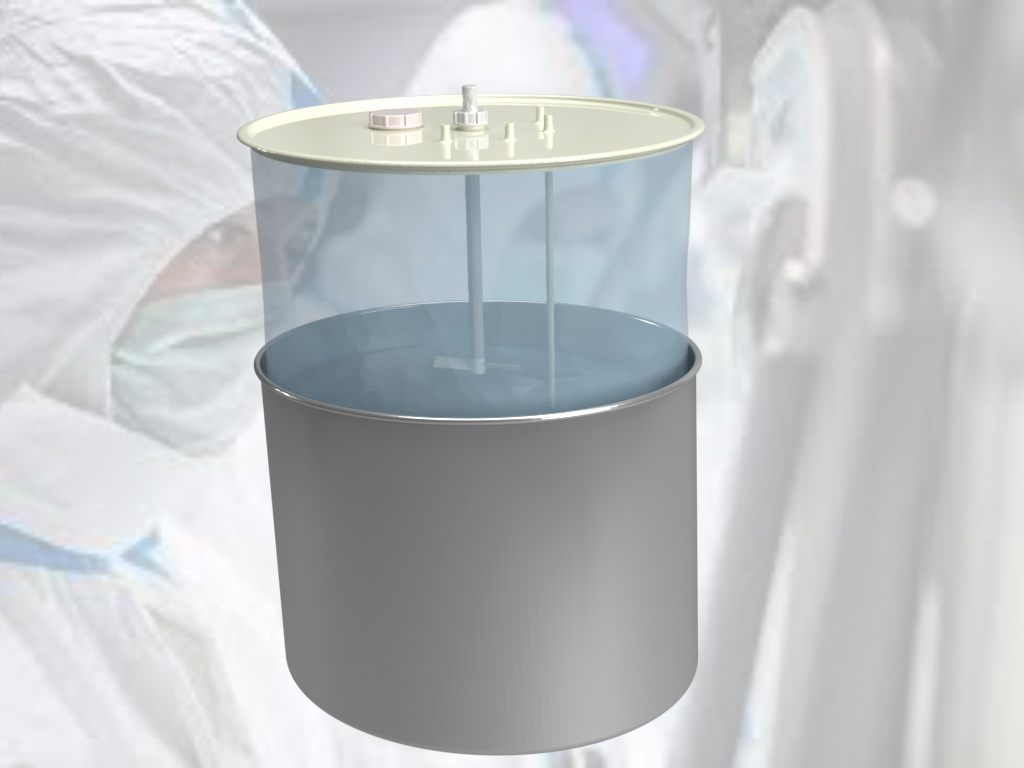

standard drum LD-PE Inliner drum Bioreactor with single use Inliner system

Inliner for process tanks

Dimensions:

The sizes of inliner bags are individually adapted to each tank and available in sizes from 0,5 L up to 1500 L. Filling/ emptying nozzle on top allowing proper filling and safe discharge.

The circumferential liner is fixed at neck ring of IBC manhole or lid of drum. The basic material of the inliner are LD-PE foils, compound foils, thermo formed outlets etc.

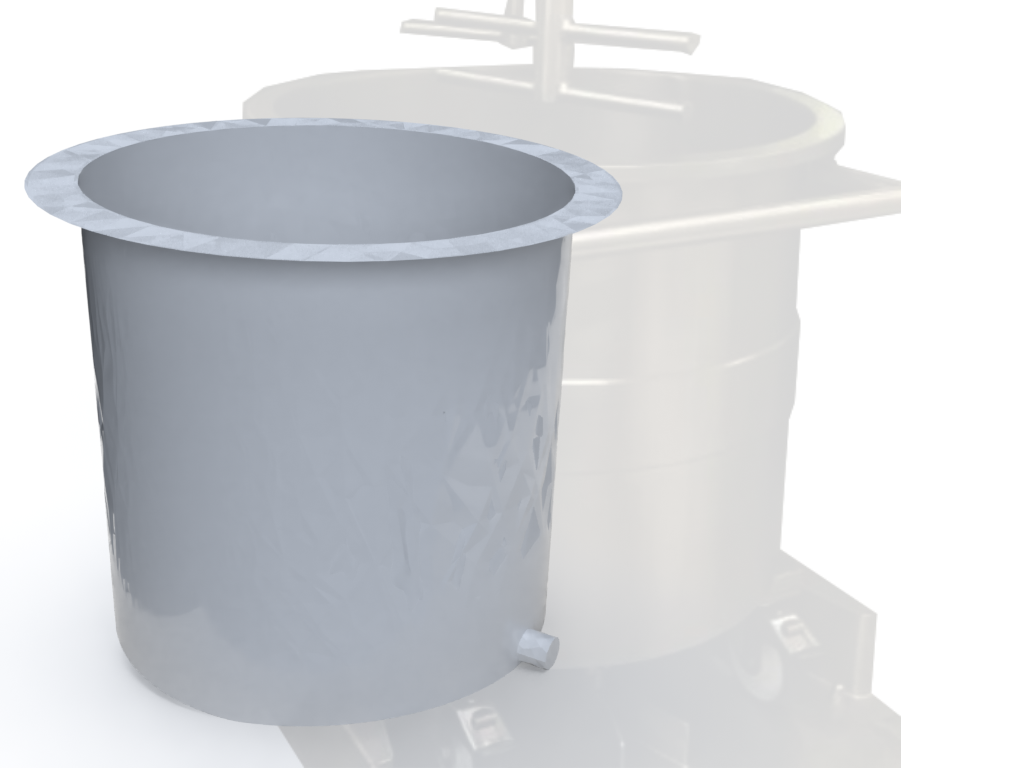

Formed Inliner /– thermo formed blow-molded, shaped bottom liner

This PE liner is made from polyethylene in a blow-molded/thermo formed extrusion process. Heated and shaped inliner outlet tools are formed acc. to your tank bottom line so that the inliner fits without pockets or folding effects. The Formed Inliner is designed vacuum pumps discharge or and mixing operation.

Your benefits:

- Customized formed inliners are perfectly shaped to outlet bottom of the container to avoid wrinkling or formation of pockets

- emptying by vacuum pumps: no residues

- reduced cost: inliners turn your one way into a multi way packaging

- reduced cleaning cost: Formed Inliners avoid contamination of drum/container

- useable in reconditioned drums/container

Special sized Big-Bags (FIBC):

Benefits:

- Individual manufacturing of all round or square shaped big bags with volumes from 10 to 1,000 liters

- option: PE Inliner customized design, no wrinkling or formation of pockets by using thermo forming tools

- special filling/discharge armatures avoid dust exposure or odor release

- upon request: sterilized (PE Inliner e-beamed/X-rayed) available material FDA/EG1935/2004