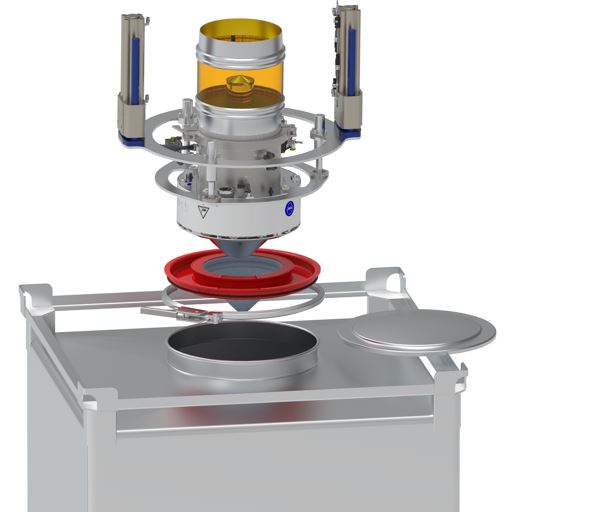

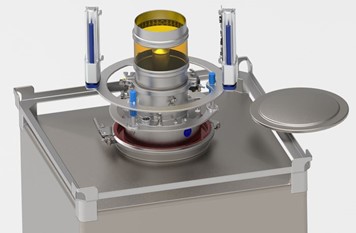

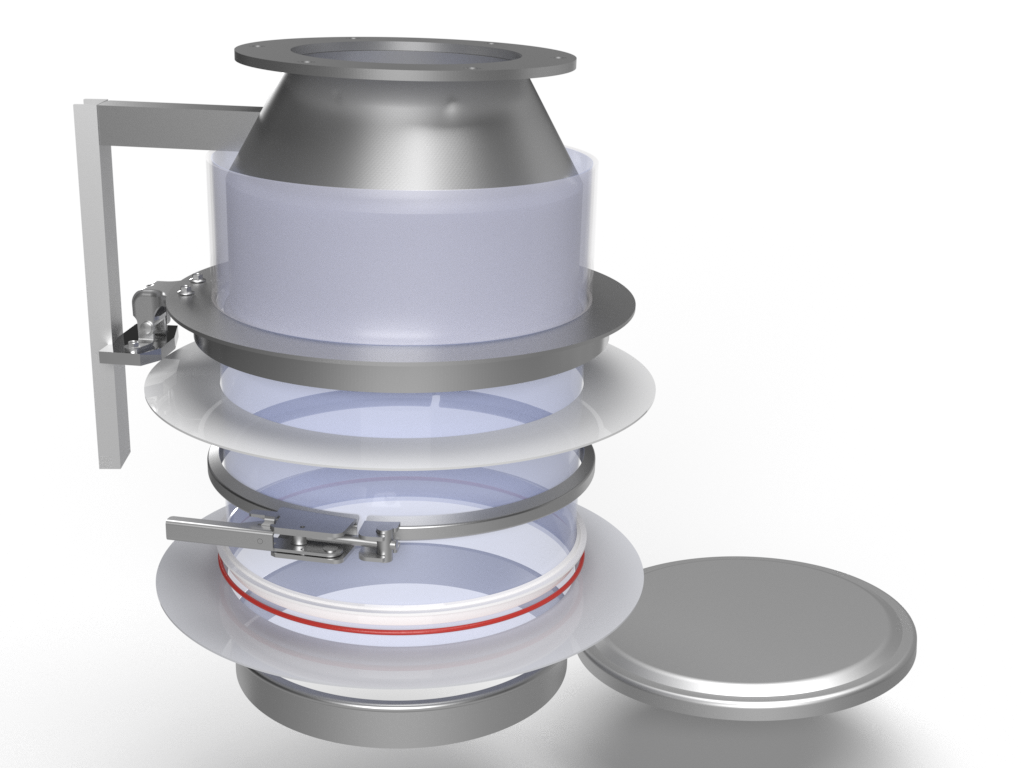

- adapter cover (red) for IBC manhole nozzles available in NW 600 /500 /457 /400

- lid adapter fastened via the standard clamping ring of the manhole cover various adapters available for IBC containers, big bags or barrels

- PLC controlled docking

- manhole standard lid as closure to the environment still fit with mounted passive valve adapter on manhole nozzle of IBC

- segregation free filling principle

– OEB 3 containment level

Filler heads -reduced dust level

low-dust filling adapters are available with various docking plates and large-area seals. Furthermore, there are docking nozzles with expanded terminals for different barrels, octabins or containers. The docking unit becomes pneumatic. This never loses contact during filling thanks to its spring bearing and mechanical locking. In practical use, the stations are placed directly under silos, mixers or dryers.

- Steel and stainless steel frame

- Suitable for all container sizes

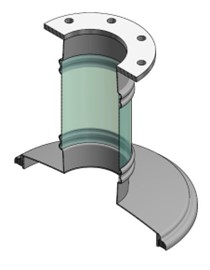

- Docking adapter with large-area seal for different drums, octabins and containers

- docking nozzle with expanded clamp for consistent round openings Combination of docking nozzle with expanded clamp

- with adaptable docking plate Seal in different materials

- Weighing possible Vibrating table for heavy-flowing products

- Height adjustment (manual, electric, pneumatic)

- FDA / Food compliant according to EC 1935 / 2004

control cabinet also avaibale in ATEX 20/21 design

- filler Head: operating temperature up to 200°C

- soft PTFE gaskets

- acid and solvent resistant

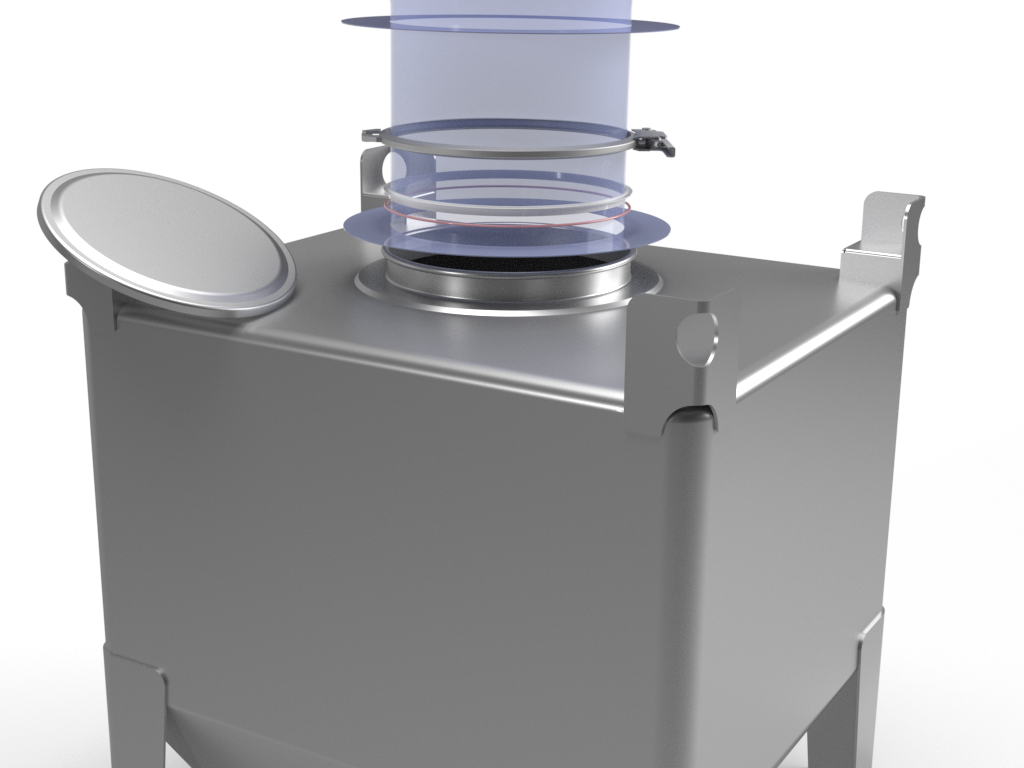

Dust free Filling of IBC by endless Liner System

LD-PE Endless Liner Filling system for manholes of container

Application:

dustfree filling of standard IBC container by means of Endless Liner Filling System for safe and contained powder transfer.

Advantages:

- High Product- and environmental protection

- Adaptable to all standard IBC Container manhole sizes

- simple Handling

- Foil individually manufactured, FDA, antistatic

- 25x filling set per unit

- Adaptable to existing imstallation by flange or locking ring

What goes in must come out : in addition to customized IBC bulk container and filling stations, we also have the corresponding discharge stations.

General:

With our IBC container filling stations for bulk containers, octabins, drums and big bags can be filled quickly and easily without losses, cross-contamination and dust pollution. The filling adapter can be pneumatically moved up and down. The filling of the containers can be optimized with a vibrating table. This is used to compress the product angle of repose in the container.

Operation is carried out via an application-compliant and simple control system. Of course, the system can also be integrated into a process control system. If required, a design according to ATEX is possible. Our individual customer solutions in the field of container and drum handling MRC Anlagentechnik differs from the requirements of our customers and almost always has an individual touch.

Every system is therefore custom-made. In linear systems, the container to be filled is transported to the individual filling point and the specified product quantities are filled. A flexible connection enables highly efficient decoupling of the filling adapter and balance and prevents force connections. After completion of the filling, the docking adapter is lifted back from the container. The optional container lid can be reattached with the clamping ring for protection. The now hermetically sealed container can now be transported to the next process step. Environment, employees and medium are securely separated from each other.